Industrial Automation

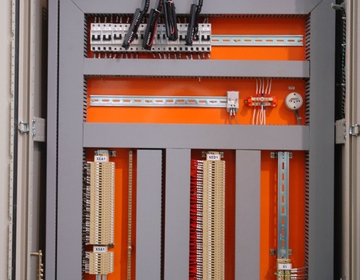

We offers a wide variety of standard and custom control systems, designed to provide functionality and reliability. Whether you're looking to retrofit existing electro-mechanical controls, or require new, state-of-the-art PLC /DCS and HMI systems, our team of process automation specialists can help design a configuration tailored for your application. Because we believe that it is easier to build it right than it is to repair a reputation, our custom control panels are fabricated in strict accordance with U.L. 508A standards. In fact, we are one of the few water treatment, Sugar refinery, Food Industry automation solution providers that have chosen to undertake the U.L. certification process. This ensures that our control products are held to the highest possible standards. That's because we know you expect nothing less!

We always do our best to exceed our customer’s expectations and as such we are now a “Rockwell Automation OEM Machine/Equipment Builder”. This means we have chosen Allen Bradley hardware and Rockwell Software as our automation platform in the systems we manufacture, allowing for the automation of key processes.

We have standardized our controls on Compact Logix processors and PanelView Plus 6 & 7’s for operator interface acting as our human machine interface (HMI). This allows our Engineering and Automation team to create a system that allows the user to monitor and control just about everything one could imagine via user interface.

Our panels and engineered equipment are designed for easy troubleshooting with the aid of detailed electrical schematics, P&ID’s and mechanical drawings. These enhancements are what place Water Innovations ahead of the competition.

Our team of experienced professionals helps us select our vendors by analysing them on various parameters such as goodwill in the market, manufacturing facility, financial position, transport system, etc. These highly qualified professionals are completely trained by our industry experts for methodical understanding of their particular domain for delivering the finest products by understanding customers requirements. They keep a regular check on the market...

Typical Features

- Hoffman/Rittal NEMA 4X painted steel enclosures

- Allen-Bradley/Siemens PLC's

- Allen-Bradley /Siemens HMI's

- Allen-Bradley/Siemens VFD's

- Allen-Bradley //Siemens power supplies

- Parker /Rotex solenoids

OPTIONAL FEATURES

- Hoffman /Rittal NEMA 4X stainless steel enclosures

- Hoffman NEMA 4X fiberglass enclosures

- GE Fanuc hardware

- Modicon hardware

- Siemens hardware

- SCADA packages

- Remote I/O

Industrial Controls Automation

- Email alerts of events

- Remote monitoring and Control

- Alarm events and alarm historian

- I/O fault monitoring and direct visible I/O monitoring

- Motor and pump run time odometers with user adjustable maintenance service alarms