Ion Exchange

Custom Water Treatment Systems

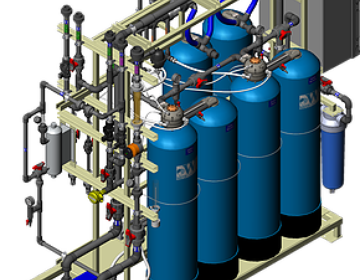

Escon Filter has grown to become a leading OEM of custom water treatment systems, specializing in application-specific, cost-effective and reliable solutions for industrial, municipal and ultrapure clients. Our products include a variety of state-of-the-art technologies, expertly designed to meet each client’s specific needs. From primary filtration to distribution and recycling, Escon has the capability to tackle the most complex water treatment challenges. In addition to superior technology, Escon provides outstanding aftermarket service solutions including our renowned, Support and Partnership program called Advantage Service Assurance Program (ASAP).

Food & Beverage

Escon offers a comprehensive array of water and wastewater treatment equipment and technologies for the food and beverage industry. From filtration and softening, to membrane separation and disinfection systems, we have the process water spectrum covered. Our wastewater treatment technologies include chemical/physical, biological and recycling, providing you with the tools you need to achieve regulatory compliance, minimize waste and reduce BOD levels.

We design, build and install complete water and wastewater systems according to your specifications. Whether you need high quality process water or wastewater treatment, we can deliver a cost-effective, custom-tailored solution that will exceed your expectations.

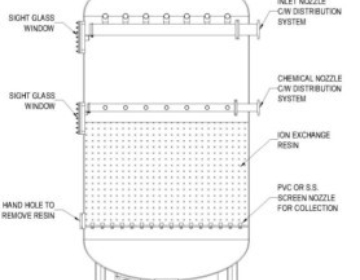

Ion Exchange Description

An ion exchange system consists of a tank containing small beads of synthetic resin. The beads are treated to selectively adsorb either cations (positive) or anions(negative) and exchange certain ions based on their relative activity compared to the resin. This process of ion exchange will continue until all available exchange sites are filled, at which point the resin is exhausted and must be regenerated by suitable chemicals.

Features

- Shop-built, modular designs delivered for quick, easy installation and start-up.

- High-efficiency, multi-bed designs to produce waste rates that match available disposal options while minimizing regenerate inputs and waste products, as consumables and waste handling drive the overall cost of contaminant removal in many locations.

- Redundancy and control system capabilities that provide the data system set-point optimization needed to ensure quality goals are continuously met while minimizing operating costs.

- Sensing, data logging, and remote communication capabilities to enable operators to review and attend the unit as needed either from a distance or on site.

Common Applications

- CIP/Clean-up Water

- Canning

- Boiler Feed

- Cooling Water

- Ingredient Purification

- Rinse Water

- Brewing

- Process Water

- Container Cooling

- Carcass Washing

- Implement Sterilization

- Mixing & Dosing

- Meat Packing

- Soft Drinks

- Bottled Water

- Wine & Spirits

- Juices

- Recycling

- Wastewater

- Soups/Sauces

- Dairy

- Baked Goods

Our Products and Services Include

- Media Filtration

- MF/UF

- NF/RO

- MBR

- Demineralizers

- Softening

- Ultraviolet Disinfection

- Dealkalization

- Ozone Solutions

- Process Control/Automation Solutions

- Remote Monitoring

- New Installations

- Upgrades & Retrofits

- Process Evaluation & Optimization Services

- Preventative Maintenance

- Aftermarket Parts

- On-site Troubleshooting & Repair