Brine Recovery

Brine Recovery system in Sugar Refinery Overview Sugar Refineries use an Ion Exchange technology for decoloring sugar liquor. After the resin gets exhausted, it has to be re-generated using caustic brine solutions. At present these effluents are sent to waste water station & fresh brine solution is prepared for every cycle. Applications Colour Removal from Spent Caustic Brine in Sugar Refinery Feature and Advantages Brine recovery is done without neutralizing, as was done in conventional systems. Minimal make‐up of caustic and salt is there, as no acid is required for neutralising the waste stream High flux and high temperature stability at high pH upto 13 Membrane process recovers upto 85-90% Caustic brine back into the system.

Colour concentrate further rejected as an option, making caustic brine recovery as high as 95% Low effluent loading as most of the colours are precipitated out in this new process Process Operation Raw sugar with high ICUMSA value has to be de-colorized. Two methods are used Powder Activated Carbon and Ion Exchange resins. The PAC is regenerated cake and depose to ground or mixed with press mud . The Ion Exchange method generates a lot of coloured spent caustic brine, which was difficult to manage. The new brine Recovery system developed by Hascon International state technology. Technical Specification Flow rates as high as 20-25 m3/Hr MOC – SS 316 or PP/FRP Full automation with Clean-in-place High degree of process control

Basis of the Design |

|

| Basis | 20 Hr operation in a day |

| Flow Rate | 4.75 Cum /Hr |

| Design Flow Rate | 7.0 Cum/Hr |

| Recovery Rate | 75% |

| Salt % | 10 % |

| pH | 12 pH |

| Operating Temp | 70 Deg C |

Introduction Ion-exchange decolorization of sugar syrup is completed using strong anion resin in Chloride form. Natural colorants found in cane or beet sugar syrups include hexose degradation products, melanoidins, caramels, polyphenols. They are efficiently adsorbed on strong anion ion-exchange resins at relatively high velocity or specific flow rate of 1 to 4 BV/h compared to adsorption by granular activated carbon which requires slower specific flow rate of 0.25 to 0.5 BV/h.

Therefore ion-exchange resin will require about 4 to 8 times less installed volume than granular activated carbon for the same capacity. BV/h : (m3 of sugar syrup/h) / (m3 of ion-exchange resin or granular carbon)

After adsorption on strong anion resin, colorant molecules are desorbed during resin regeneration, using a 100 g/l NaCl solution either at high pH (normal regeneration) or low pH (acid depollution).

- Description of a typical production/regeneration cycle

- Each decolorization column will complete the same production and regeneration cycle, as briefly summarized below.

- The column is initially full with water. Sugar syrup is pumped upflow in the column.

- Water is progressively displaced from the resin by sugar syrup.

- During a first step (sweet-on 1), only water is collected at column outlet and directed to water recovery.

- During a second step (sweet-on 2), dilute syrup is collected and directed to a separate sweet-water tank.

- Finally decolorized syrup is directed to decolorized syrup tank for further evaporation and crystallization.

- The total volume of sugar syrup per production will be adjusted according to the feed and outlet color, until resin are saturated with colorants.

- When maximum color load is reached on the resins, decolorization efficiency drops and the column must be regenerated.

- The column is full of sugar syrup, which will be displaced by water.

- During a first step (sweet-off 1), only sugar syrup is collected and recycled to decolorization feed tank (color is too high for directing to decolorized product).

- During a second step (sweet-off 2), dilute syrup is collected and directed to the sweet-water tank (same as for sweet-on 2 dilute fraction). Average concentration in the sweet-water tank is about 25-30 Brix. End of sweet-off 2 will be adjusted to target final Brix, which is usually 0,5-1 Brix.

- There will be a minimal sugar loss, as the small amount of sugar still present in the column will be lost during chemical regeneration of the column. This step can be adjusted during and after process commissioning, to optimise sugar loss/volume of sweet-water produced per cycle. The column is now full of water and ready for regeneration steps.

- The regeneration is completed down flow with a 9 % sodium chloride solution.

- Because of the counter-current regeneration, the upper layers of the resin beds, which are cleaner, are not contaminated with colouring materials eluted from the lower layers.

- This results in an improved efficiency of :

- The resin (longer life)

- The regeneration (less brine required for good regeneration).

- Caustic soda (NaOH) is added to the NaCl solution. This increases the pH and the elution of the colouring materials is improved.

- The caustic brine shall be filtered before entering the resin columns to prevent the resins from potentially being fouled with hydroxide precipitates.

- Occasionally, it is necessary to eliminate metallic salts and acid colorants removed by the resins and depollution is carried out before the normal regeneration. For this purpose, a diluted HCl solution is used.

- The recommended frequency for an “acid” regeneration is dependent on the incoming level of metallic salts and acid colorants and is followed by a “basic” regeneration.

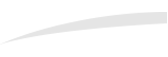

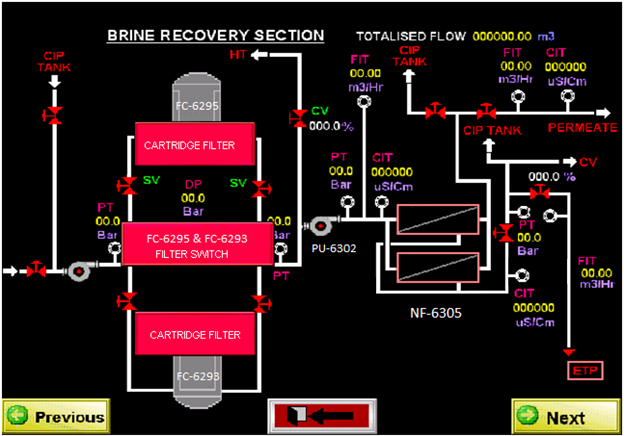

The brine solution from the IonExchange unit gets collected in underground holding tank. The concentrated brine comes and get stored in underground tanks. From the feed tank a feed pump supplies the liquid to the membrane loop. After first stage of pumping the liquid passes through bag filter, sand filter followed by two stages of cartridge filter to prevent damage to the membrane modules. The second booster pump operated with a frequency drive generates the required system pressure and cross flow for the spiral Membrine membrane modules.

The Membrine modules separate the feed solution into a Permeate (low in colour) and a Retentate (high in colour).

After each batch the system gets cleaned by a CIP. For that purpose a CIP unit (tank + dosing equipment + instrumentation) is installed and this PLC controlled with HMI interface.

Additionally water can get injected into the holding tank which is utilized for diafiltration of the concentrated retentate at the end of each batch. This has to be established during operational tests and optimisation whether this will be required or not.

All items are installed on one skid in compact form easy to access and service. The plant has been designed for automatic control system (Hardware controller for system pressure, dry run protection of pumps, supervision of pre‐filtration and Process solution.

Membrane technology is of modular design capacities can be easily adapted by an according number of membrane modules. Throughput capacities of 1 l/h up to 100m3/h are installed worldwide. That means, any site capacity can be increased at a later stage.

Membrane technology does not require any additive (i.e. chemicals) for operation. It is a separation on the basis of ionic loads, molecular sizes. Operation of BRS System at 6‐8% :

Operation of BRS System at 6‐8% :

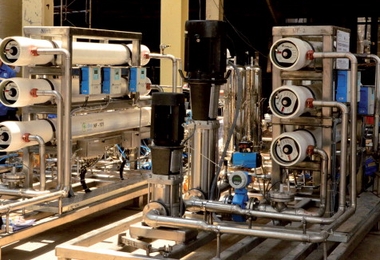

The provide system an automatic PLC controlled brine recovery system. The purpose is to filter the brine solution and separate colours and reject them to ETP, while almost clear brine to be sent back for regenerating the resin beds in the ion exchange columns. The feed from tank HT101 is sent to the system using Pump P101 and this liquid is filtered usinga basket filter FB101 , sand filter FS101 followed by duplex filter systmFC 101 /102 and FC 103/104. The differential pressure under choked conditions by pressure transmitters decides the flow switch over using the solenoid valves.

The liquid passes through a VFD controlled booster pump P102. The conductivity meters, pressure transmitters and flow transmitters transmit values on the HMI. The pressure/flow can be increased or decreased using the VFD and set values can be given during optimisation of the system.

The Retentate line is controlled by control valve CV 101 and the ratio ofrecycle and drain is decide of the quality of the retentate achieved.

Continuous permeate is collected and the conductivity and flow are monitored on a regular basis. Interlocks can be incorporated based on the requirements.

After the normal operation cycle is over, then on a daily basis the membranes will be cleaned and a CIP procedure as specified will be followed. The feed pump will be used to carry out the cleaning , draining cycles. The draining has to be manually monitored.

CONTROL DESCRIPTIONThe PLC system shall be based on advanced architecture in controller, power supply, communication and designed to accept all the analog signals for auto control and digital signals for start/stop logic using Ladder Logic. The PLC will be mounted in inside the free standing vertical SS Cabinet of IP 54 Rittal Make. Cabinet shall have processors, IO racks, power supply &marshalling rack for connection of field instruments. The PLC system shall Ethernet interfacing facility provided by you. The minimum design features of PLC should include the following:

- The PLC shall be provided processor, power supply (24 VDC) and communication port. PLC shall communicate to 8” colour HMI. Necessary hardware/ software, Interconnecting cable & converters shall be provided and Preparation of Ladder logic programming and downloading in online mode without interrupting the control operation.

- The scan time of the PLC shall be of the order of 50 milliseconds.

- The Analogue and Digital Input /output shall be provided noise filter with Galvanic/ Opto - Isolation from external control source.

- The Input modules to be suitable for processing the field signals. The Outputs and inputs will be short circuit proof and protected by fuses.

- The memory will be non-volatile or battery backed up as required.

- The Input/output also to be provided with protection against reversal of polarity of supply voltage.

- The PLC programming language shall be based on Ladder logic. The ladder logic should be programmable from Panel view system (Uncountable tag nos. with run time & development software).

- 10 % extra relays for multiplying signal to be considered for distributing signals min I/O modules for future provision.

- License & hard key for MMI (MMI software with Ladder logic software) shall be provided in the name of end user.

System consists of Triple effect forced circulation evaporator to concentrate the brine from 7.5-8.0% to about 45 %. Material of construction of the shell is SS304 and the tube sheet of SS316 Ti & the tubes of SS316 Ti to avoid the corrosion of brine solution. Concentrator is working under vacuum. Low pressure steam is used a heating media. Each body is equipped with pre heater .The feed brine solution is heated in the pre heater before it feds to the evaporator body with the same body vapour. Each evaporator vessel is provided with recirculation pump which will maintain the required vetting rate required for each calendria and the excess brine will fed to the next vessel recirculation pump through the control valve provided in the recirculation pump delivery line based on the vapour separator level transmitter level.

Level in each vessel will be maintained based on the vapour separator brine sensed by level transmitter. Each vessel vacuum and temperature will be monitored through respective vacuum and temperature transmitter. Steam required for the first body calendria will be controlled through control valve. Conductivity transmitter provided in the concentrated pump discharge will measure the conductivity of the concentrated brine and based on the set point conductivity the three way valve either discharges into product outlet or fed inlet or drain. The plant is designed for 20 hrs working basis and balance four hrs for the CIP of the evaporator vessel.

Spray Drying:Dryer used for drying the concentrated brine will be Vertical agitated Thin Film Dryer. Heating media will be low pressure steam. The inner shell will have scrapper for scrapping the product over inner shell in order to get a thin uniform film, which is driven by electrical geared motor. This will be jacketed, and properly insulated. The concentrated brine will fed into the inner shell through atomizer nozzle at the top whereas the steam entry at the outer jacket at the bottom. The brine will get dried while contacting the heated steam jacket and scrapped with the help of rotating scrapper. The dried crude salt will be bagged at the bottom of the Vertical agitated Thin Film Dryer. The vapour generated will be condensed in the surface condenser and the vacuum is created through water ring vacuum pump.

Steam to the outer jacket will be controlled through control valve and the temperature of the outer jacket, temperature of the vapour, surface condenser cooling water inlet and outlet temperature will be monitored for proper drying of the brine.

The plant is designed for 20 hrs working basis and balance four hrs for the CIP/cleaning of the Dryer.

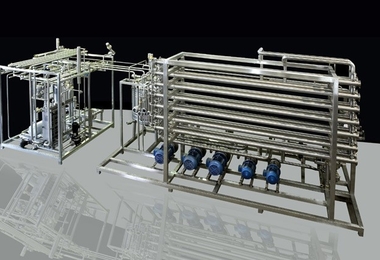

Poresep-Membrane System

The membrane elements are grouped together in stainless FRP housing-modules. The modules are specially designed to resist high thermal, chemical & mechanical stresses. Each element can be easily fitted & removed individually. Some advantages of proesep-membranes are highlighted below:

- Brine recovery will be without neutralizing as done in conventional systems.

- Minimal make‐up of caustic and salt will be there as no acid neutralization is done.

- No acid dosing in the process, so low operating costs.

- High flux and high temperature stability at high pH upto 13.

- Colour concentrate can be further recovered as an option, making caustic brine recovery as high as 90‐95%.

- Low effluent loading as most of the colours will be precipitated out in this new process (optional).

- Low Operating cost.

| Quantity | 1 Set – elements with Housing |

| Material Vessel | FRP Vessel |

| Quantity | Elements arranged in arrays with 4Housing |

| Element Type | Poresep-Membrane – High pH –Modified |

| Interconnecting pipe | Complete SS316L |

Brine Filter

| Model | MS Fabricated |

| MOC | MSRL Coated IS 226/2062 |

| Type of Flow | Down Flow |

| Hydro Test Pressure | 5.5 Kgs. |

| Vessel Dia-mm | 2800-mm |

| Vessel Height | 1800-mm |

| Over all height | 3850-mm |

| Vessel / Disend Thick. | MS (08-mm Shell 10 mm Disend) |

| Distribution System | Spalash Type |

| Collection System | Botm Plate Perforated Type |

| Treated Water Quality | As per Norms <25NTU |

| Valves | Butterfly Valves |

| Pipelines | 150 NB `C` Class |

| Inner Protection | Non Toxic Natural Rubber lined |

| Outer Protection | 02 Coat Red oxide & Enamel Paint |

| Media | Pebbles, Gravel, Coresilex, Super Sand |

| Qty. Of Media | 8500 Kgs. |

| Back Wash Frequency | Once a day |

| Pressure Drop. | 0.5 Kgs |