Tank Agitator

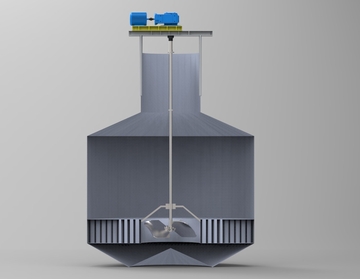

Tank Agitator the compact agitators are designed for open vessels or those which have a low pressure. Their robust design and excellent smoothness when operating make them extremely reliable, even when mixing media with high solid contents. Further advantages are the low overall height and the modular design which ensure maintenance at low cost and an easy modification of the agitator, if necessary. Our specially developed impeller for process, reduce energy consumption. Bases on extensive fluid dynamics studies, their unique shape make them up to 400% more efficient then impeller with a standard pitch. Besides minimizing energy loss, our impeller operate at reduced speed without reducing pumping capacity. Compared to agitator with conventional impeller, they thereby lower agitator power consumption by up to 80%.

Our goal is to provide mixing and blending equipment that meets your process needs at an affordable price. We only offer high end 24/7 duty industrial and sanitary mixing equipment that is designed to last for years in aggressive plant environments. We always want to know as much about your process and specifications so we can help suggest the right mixer for the job.

Providing mixing assistance, with support and service to you, our customers, is our most important goal.

Applications We Work With

- Sanitary mix tanks & vessels

- Sanitary vessel/mixer/valve packages

- Sanitary mechanical seals

- Industrial agitators

- Sanitary mixers

- Custom mixing packages

- Lab production-scale equipment

- Specialty mixers

Mixers:

Portable mixers, top entry mixers, side entry mixers, in-line mixers, bottom entry mixers, static mixers and custom designed mixers.

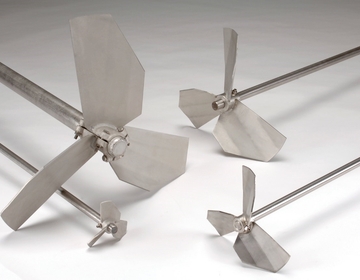

Impellers:

- AL Hydrofoil (low solidity hydrofoil)

- AM Hydrofoil (mid solidity hydrofoil)

- AH Hydrofoil (high solidity hydrofoil)

- HP Impeller

- PBT Impeller (Pitched Blade Turbine)

- RSB Impeller (retreat curve turbine)

- VBT Impeller (Vertical Blade Turbine)

- RD Impeller (Rushton Design Impeller)