Self-Cleaning Filter

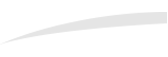

Multi-function self-cleaning filter is researched and developed based on auto filter. It's suitable for harsh conditions where there are various types juice of impurities. The design is multi-functional and structured. The cleaning component uses sucking or scraper. It's able to clean impurities adsorbed on the filter element surface very effectively. When the filter pressure difference between the inside and outside of the filter mesh reaches the default values or the regular cleaning. Products Description Self-cleaning backflushing clarified filter, also for highly viscous media and high temperatures.

Fully automatic backflushing filters are primarily used for the filtration of clear juice, Raw melt, spray water or River water and work almost wear-free. Due to its simple backflushing system, this self-cleaning filter can also be used for highly viscous media and in high temperature areas. The cleaning process is possible without interruption of filtration. To remove impurities from clarified cane juice such as bagacillo, cellular materials, and residual flocs, to replace current DSM screen or cloth screening methods. The advantages of these new backflush technologies are: - Virtually no power consumption (except for automatic valves) - Self cleaning system - Virtually no recycle of juice with bagacillo – typically 0.001% - No heat loss – totally enclosed insulated system - Virtually Maintenance free

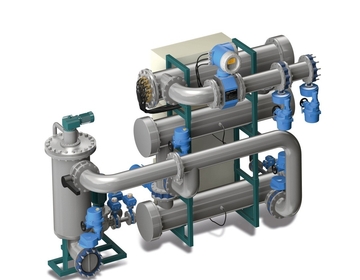

Working Principle:

The waste water enter into the filter, In filter process, the fine screen surface gradually accumulates the impurities from the water, then form the filter impurity layer. Because the impurities accumulate in inside of the fine screen, then forming a pressure difference inside and outside of the fine screen.

When the differential pressure system reaches the preset value, the system of water supply is not interrupted, open backwash valve or drain valve, the waste water outlet from the drain valve. While the pressure go down in the hydraulic motor chamber and dirt collector, then the suction nozzle of suction assembly begin suction process: there is a very strong backwash water flow to the outside, the suction nozzle produce a suction power plus the flow power through the hydraulic motor. Because the hydraulic piston pressure go down, lead the dirt collector rotate around the axis of rotation to move, so perfectly clean the inner surface of fine screen. This type of filter is simultaneously provided with a timing controller, which can regular blowdown in certain time.

Product Features:

- Compact body, firm and reliable structure

- Small backwash water consumption, low water pressure demand

- High filtration precision, suitable for all kinds of water quality

- Small backwash pressure reduction, no effect on normal water supply

Applicable Typical Industries and Liquids

- Applicable industries: Water treatment, steel, pulp and paper, mining, petro-chemical, machining, municipal, irrigation etc.

- Typical applicable liquids: Groundwater, seawater, lake, reservoir water, pond water, cooling water circulation, frozen water, high and low voltage gush to drench water, squirt water, heat water, seal water, bearing cooling water, oil wells note water, process of circulating water, machining coolant, cleaning agents, cleaning water, etc.

- Filtration function: Remove large particles, purify liquids, protect critical equipment.

- Filtration type: Back-flushing filter, automatic continuously online filtration

Automatic Self Cleaning Strainer/Auto Multi-Cartridge Back Flush Filter

Product Description

Standard specifications of the technical parameter table:

Models |

Filter core No. |

Filter core specification |

A(mm) |

B(mm) |

C(mm) |

D(mm) |

Inlet/Outlet diameter |

drainage outlet Size |

Refer Flow |

BCM300 |

8 |

57*650mm |

1350 |

265 |

905 |

300 |

DN100 |

DN50 |

70 |

BCM400 |

12 |

57*650mm |

1420 |

265 |

945 |

400 |

DN150 |

DN50 |

150 |

BCM500 |

22 |

57*650mm |

1520 |

290 |

1000 |

500 |

DN200 |

DN65 |

250 |

BCM600 |

30 |

57*650mm |

1600 |

290 |

1050 |

600 |

DN250 |

DN65 |

300 |

BCM700 |

26 |

80*650mm |

1700 |

335 |

1050 |

700 |

DN300 |

DN80 |

550 |

BCM800 |

38 |

80*650mm |

1800 |

335 |

1050 |

800 |

DN350 |

DN80 |

800 |

BCM1000 |

50 |

80*650mm |

2200 |

335 |

1150 |

1000 |

DN400 |

DN80 |

1200 |

BCM1200 |

76 |

80*650mm |

2400 |

365 |

1200 |

1200 |

DN500 |

DN80 |

1800 |

Specifications:

Applicable Liquid |

Water and liquid of low viscosity(<40cps), contaminant<300ppm |

Lowest Working DP |

Differential pressure between the outlet and discharging outlet >0.15MPa |

Filtration Rating |

50-2000μm |

Design Pressure Class |

0.6MPa/1.0MPa/1.6MPa/2.0MPa |

Design Temperature |

0-95°C |

Flowrate Range |

17—8000m³/h |

Filter Area |

4970cm²-89530cm² |

Self-cleaning DP |

0.05MPa—0.07MPa |

Control System |

parallel control of differential pressure and time |

DP Instrument |

Differential pressure transmitter, differential pressure switch |

Gear Motor |

120W, three phase, 380V, protection class IP55, CCWU |

Inlet and outlet size |

2"—24" |

Connection Standard |

flange,HG20592-2009(Standard Design), HG20615-2009(ANSI B16.5 compatible) |

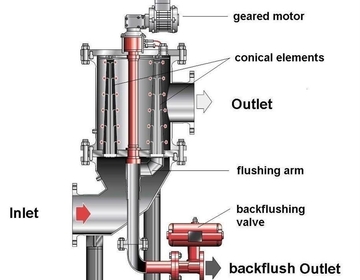

Filter Element |

V-SLOT series slotted screen, material 316L/SuperDuplex/Ti2 |

Wet Part Material |

304/316L/CS, special material available (such as 904L, duplex S.S.) |

Inner Lining |

Epoxy, PA11 for CS Housing or special anti-corrosion requirement |

Housing Sealing Material |

NBR(Standard/VITON(FKM) |

Discharging Valve |

Pneumatic stainless steel valve or butterfly valve, protection class IP65 |

Facility Supply |

Compressed air: clean and dry, 0.4-0.6MPa, 380V AC, 24V DC |