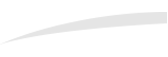

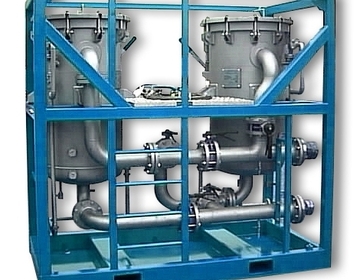

Duplex Filter

The skid mounted duplex filters are always produced on customer demands and are always customer made. A duplex filters can be produced with two cartridges, vessels, bags or can be combined with a cartridge or bag vessel and can even be switched between a cartridge or bag filter or as strainer. The skid mounted duplex units can be produced in accordance with PED ASME VIII div

Advantages of the duplex strainers

During normal operations the strengths of the duplex filter is that it can be completely operated maintenance-free, Long lifetime Easy to use Low price, high quality Application, except for checking the seals and cleaning of the filter element. With two filter chambers connected with a changeover valve one chamber is always in operation while a clean filter chamber is in standby mode. Duplex filters are primarily used where shutting down machines and systems are not practical or highly uneconomical, for example, in the maritime or the production industry.

How the duplex strainer works:

Filtration phase

While one filter chamber of the duplex strainer is in filtering mode, the other chamber is always with a cleaned filter element off line. The liquid passes through the filter element and over time the pressure drop in this filter chamber will increase. The increased pressure drop is an indication that particles have been accumulated and cleaning is required. Optional a differential pressure indicator can be installed on the duplex strainer.

Cleaning phase

By activating the switch plug, the clean filter chamber will be put in operation and the dirty filter chamber is simultaneously switched off. Switching to the clean filter chamber is carried out without a pressure surge.

For cleaning, the contaminated filter chamber is depressurized by the vent screw, the housing cover is removed and the filter element has to be removed. The filter element is cleaned by flushing it with a cleaning fluid and subsequently blown out using compressed air

Technical Specifications |

||

|

TDW 610-50/40 |

TDW 610-50/40-4B |

Number of Cartridges per vessel |

50 |

50 |

Number of Bags per vessel |

0 |

4 |

Maximum working pressure |

101.5 psi (7 bar) |

101.5 psi (7 bar) |

Maximum working temperature |

158 °F (70 °C) |

158 °F (70 °C) |

Maximum Design pressure |

18 bbl/min (172 m3/hr) |

18 bbl/min (172 m3/hr) |

System Design Features |

Standard serial/parallel configuration. |

Standard TDW 610 type: 50 cartridges per vessel. |

Suitable for non-hazardous fluids (Fluid Group 2) |

Innovative push lever and swing-away vessel lid, easy to operate. |

Swing-bolts and nuts for quick opening. |

Self sealing, service friendly cover gasket. |

4" Butterfly Valves (SS-Disk). Easy to operate. |

Certified hoisting slings lifting lugs and forklift pockets. |

Safety valve set at 101.5 psi (7bar). |

Offshore DNV 2.7-1 / EN12079 frame. |

Optional |

ASME Vlll design |

High pressure (10 bar). |

Other construction materials. |

Other cartridge configurations. |

High Flow 6" piping |

Flanged connections |

Integrated C-Pump |